High Visibility: Tim and TTLMakerspace Deliver PPE by Bike

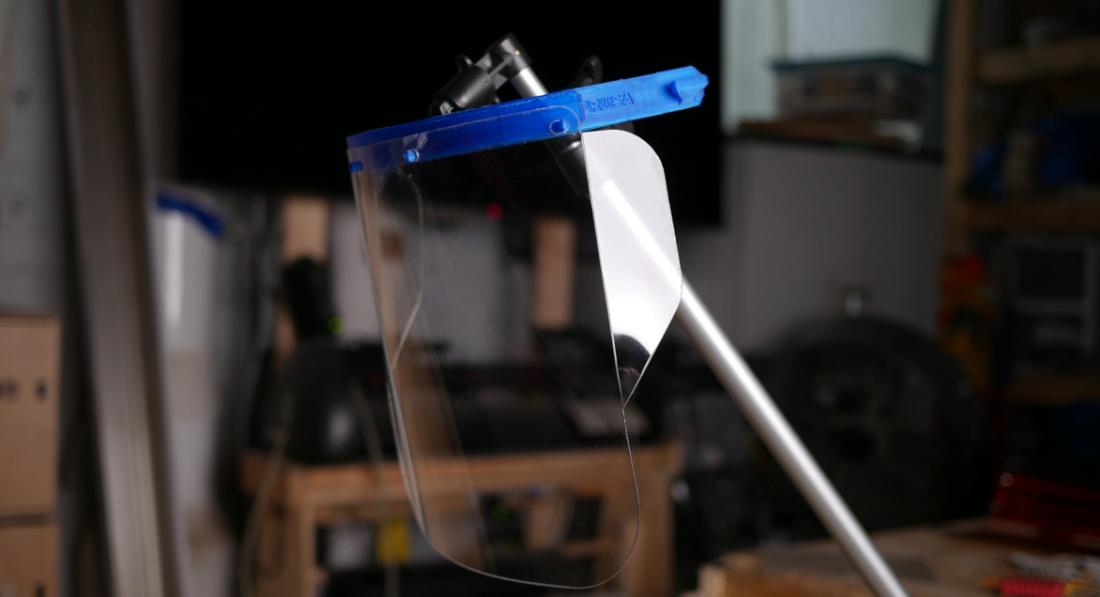

Tim Willison showing off a part for a 3-Hole Face Shield

In the last two High Visibility profiles we spoke with frontline workers; people that ride their bikes to hospitals every day to do their part in keeping people healthy. But what protects them? They need personal protective equipment (PPE) to stay safe and prevent infection from spreading. That’s where Tim and TTLMakerspace come in, the subjects of this High Visibility.

High Visibility: Tim and TTLMakerspace Deliver PPE by Bike

In one of his daily press briefings at the beginning of the COVID-19 pandemic, Prime Minister Justin Trudeau specifically called on people who have access to 3D printers, to come up with creative solutions for the personal protective equipment shortage the country was experiencing. That’s when Tim Willison and the team of makers from the TTLMakerspace sprung into action.

The team of 15 makers began running their 3D printers at home to make face shields for frontline healthcare workers, making specific designs to suit the needs of every hospital. Tim says that most makers are running their printers 24/7.

Tim Willison

Before COVID-19, the TTLMakerspace was a hub of activity that allowed individuals and groups access to equipment like printers, laser cutters and a full woodshop so they could make their dreams into reality. Members, partner organizations such as the StopGap Foundation and the Alzheimer’s Society of Toronto, and internal workshops all made up the vibrant day-to-day of the TTLMakerspace.

Everything changed when COVID-19 struck and Toronto began to shut down. Having people come in and use shared equipment in a tight space was no longer an option. TTLMakerspace had to close its doors to the public, but the essence of the organization lived on.

The small staff group at TTLMakerspace began organizing the contactless drop offs for the raw materials and picking up the finished PPE. For Tim, the easiest and safest way to do this was by using his folding e-assist bike.

On a typical day Tim spends a lot of time organizing and doing paperwork while the makers are running their printers non-stop. Tim is ensuring that hospitals and seniors homes are satisfied with their products, people are following safety protocols, and making sure every product is traceable back to the maker (in case anyone were to get sick). All of this can be time consuming, but it’s worth it for Tim when the day’s delivery route is solidified and he can get outside and play PPE connect-the-dots. Tim gets on his bike with a load of production materials and does contactless curbside pick up and drop off. Once the PPE is completed, they are delivered to frontline healthcare workers locally in the GTHA.

Video of Tim going through his daily routine and picking up and dropping off supplies.

Tim starts from TTLMakerspace at the Centre for Social Innovation - Spadina (Cycle Toronto's home) and travels as far as the Junction and Roncesvalles, stopping at makers’ houses along the way. He tries to stick to bike lanes and says that multi-use paths like the West Toronto Railpath are his favourite part of the trips. Even when he can’t use bicycle infrastructure, Tim says that riding on the road has been easier because there are less drivers on our streets. With that in mind, he said something he’d like to see fixed is potholes. Tim’s folding bike, while compact and easy to store, has relatively small wheels that are especially affected by potholes. Navigating around these hazards can mean being pushed out into car traffic or risking damage by hitting the broken pavement.

Medium-duty Face Shield produced by TTLMakerspace makers

Since the operation got up and running, over 1,000 pieces of equipment have been delivered free of charge to frontline workers. You can see a running tally here. A huge part of the TTLMakerspace’s revenue comes from donations, especially during this time while the rest of their operations are on hold. Tim told us that at times they’ve had to slow down production because they’ve run low on production materials for the printers. If you have the ability to help out, see what you can do here.

Previous High Visibility: Rosa Phillip

Cycle Toronto’s mission is to make our city a safer, healthier, and more vibrant cycling city for everyone, so that people like Tim can get where they’re going. For as little as $5 a month our members help us advocate for cycling at City Hall, do educational outreach, and encourage people to take up cycling as a fun, healthy, and affordable form of transportation.